ROCKSTEAD BLADE SHAPE

Rockstead are making their knives with a two different blade shapes at the moment. HONZUKURI and SHINOGIZUKURI.

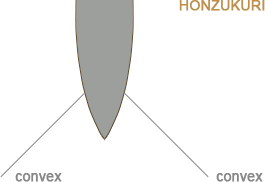

HONZUKURI BLADE SHAPE

Knives with HONZUKURI blade shape was inspired by traditional Japanese sword. Both sides of the HONZUKURI blade are convex surfaces. These cutting edge shape function is perfect. As a result of applying Japanese sword's geometry to the knives, knives with HONZUKURI has perfect cutting ability and very strong blade.

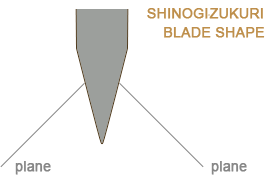

SHINOGIZUKURI BLADE SHAPE

In blade shape SHINOGIZUKURI, both sides of the blade are composed of the plane. (SHINOGI is japanese name of the line, made by two surfaces) During researching the blade cutting ability, Rockstead ascertained that the angle in a slight part in the tip of the blade influences sharpness. As a result of this, Rockstead understood that for the comfort cuting the edge angle in a part close to haft of the braid has to be 30 degrees and the angle in the point of the braid has to be 24 degrees. (Rockstead adjusted the angle to 30 degrees because the haft side was a place in which power came most, improved toughness, and made it to 24 degrees aim sharpness because the tip of the blade was a place in which power did not come easily. This angle has changed continuously) The blade that matches to the human engineering by this technology appeared.

In blade shape SHINOGIZUKURI, both sides of the blade are composed of the plane. (SHINOGI is japanese name of the line, made by two surfaces) During researching the blade cutting ability, Rockstead ascertained that the angle in a slight part in the tip of the blade influences sharpness. As a result of this, Rockstead understood that for the comfort cuting the edge angle in a part close to haft of the braid has to be 30 degrees and the angle in the point of the braid has to be 24 degrees. (Rockstead adjusted the angle to 30 degrees because the haft side was a place in which power came most, improved toughness, and made it to 24 degrees aim sharpness because the tip of the blade was a place in which power did not come easily. This angle has changed continuously) The blade that matches to the human engineering by this technology appeared.

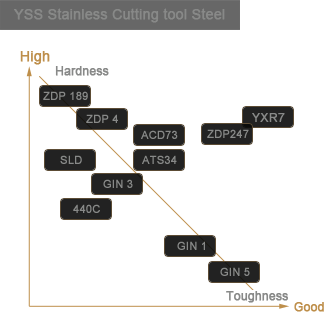

STEEL MATERIAL

The steel material which Rockstead are using for their blades at the moment is "high speed tool steel" YXR7 and stainless steel ZDP189. Both of these steels were made for the cutlery by Hitachi Metals Ltd.

YXR7 (MATRIX HIGH SPEED TOOL STEEL)

It is a steel material with the wonderful function made as a high-level steel material of high-speed steel. The hardening hardness is around HRc65 and the toughness is excellent. It is one of the factors that the blade do not nick even after chopping the dried bamboo. But YXR7 is a carbon steel with low corrosion resistance. To prevent the blade rust and corrosion, Rockstead are covering the blades made from YXR7 steel with DLC or TiAln coating. But for the better cutting ability coating in the tip of the blade is removed. So we recommend the blade to be wiped with the cloth after use.

ZDP189 (POWDER STAINLESS STEEL)

This steel material is high carbon stainless steel specially produced for cutlery. The hardness is HRc67 that appeared by containing the carbon of the amount that cannot be contained by the dissolution steel is marvelous. It is a steel material that concentrates the chic of the nanotech technology. We are using the clad steel to which ZDP189 was sandwiched by ATS34, or we are using ZDP189 only. Please do not cut food on the plate with this knife. Hardness is high so this knife cuts the plate. And, simultaneously this knife-edge receive damage. You cannot cut the ceramic or iron with this knife. HAP72(Steel material of phantom) We are researching a steel material that is stronger than YXR7. And, the hardness of this steel is HRc70. The prototype was completed. However and the price are considerably high so we postpone the selling. The steel better than this is not, and will be able to be called a steel material that collects the chic of the nanotech technology in the cutting steel of high hardness and high toughness now.

DLC COATING (DIAMOND LIKE CARBON COATING)

This is a coating that can be done by depositing the carbon to the knife in vacuum oven. (It's heated up to 500℃.) Surface hardness near the diamond is Hv1800. The film thickness is three microns. This coating demonstrates wonderful effect on the surface of the excellent cutting steel called YXR7. As the reason, the YXR7 has high hardness(HRc65) and high toughness. If the impact is received from the outside of the DLC coating, YXR7 catches it and doesn't cause the crack in DLC. Even if DLC is hard, the film thickness of three microns is destroyed at once if the steel material is soft.

TiAln COATING (TITANIUM ALUMINUM COATING)

As for this coating, the hardness (Hv3000) is harder than DLC, and you can scratch the surface of the board glass. The strongest blade is completed by giving YXR7 this coating. In YXR7, the tempering temperature is 580℃, therefore, there is no change in hardness even if the knife is put in the oven for the coating heated to 500℃, so you can safely do this coating.

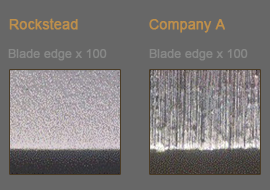

MIRROR SURFACE PROCESSING

When looking at usual knife edge through a microscope, it looks serrated like the blade of a saw. We ascertained one of the causes of a nick was the tip of these inadvertent protrusions, and we came to understand that the edge of the blade has to have a perfect mirror surface. You can confirm the different feel from a usual knife when you touch a ROCKSTEAD knife edge. Slicing a sheet of paper will confirm its unrivaled sharpness.

When looking at usual knife edge through a microscope, it looks serrated like the blade of a saw. We ascertained one of the causes of a nick was the tip of these inadvertent protrusions, and we came to understand that the edge of the blade has to have a perfect mirror surface. You can confirm the different feel from a usual knife when you touch a ROCKSTEAD knife edge. Slicing a sheet of paper will confirm its unrivaled sharpness.